In this article from Nikan West gilsonite site we want to talk about Mud loss control of drilling fluids with fiber-based material and how it works to solve this problem. If you want to know everything about drilling mud, read our other article.

Why Mud loss control of drilling fluids is important?

One of the most common problems in the oil and gas industry is choosing drilling mud during well drilling. This is important because of the cost of drilling mud, as well as the longer time it takes to drill a well and occupy a rig.

For this reason, various methods are proposed to control drilling mud. One of these methods is the use of fiber-based mud. In this article, we want to talk about this substance and how it works to solve this problem.

What is a fiber-based mud?

First of all, it is better to know about the base of the drilling mud. The base refers to the main constituent of the mud. From the past to the present, this substance has usually been water, oil or emulsion. In fact, we have water-based drilling mud, oil-based, and emulsion-based drilling fluids. But in addition to these cases, and with the increasing specialization of chemical knowledge, muds with very different characteristics have also been made. Fiber-based mud is one of them.

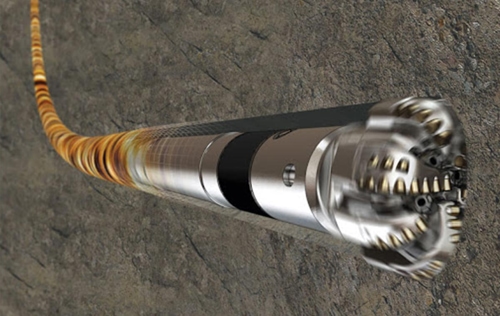

Fiber-based mud is a combination of fiber and gravels with optimal diameter; Compared to older solutions, it has more ability to control drilling loss. It is very difficult to control wells due to the physical characteristics of the cracks created in the well wall and their diameter. But the fiber-based mud, with the help of a three-dimensional network, eliminates this limitation to a large extent and does not require this information. As a result, it is much more economical and more secure than the old methods.

The most important advantage of this mud is its ability to be pumped with the help of drilling drills and it can be used in drilling operations, well cementing and well repairs.

Fiber-based mud components

The base fluid in which the fibers and grains are homogeneously placed; is the first part of this mud.

The fiber in this drilling fluid includes two types of soft and coarse fiber. This variety improves the performance of the mud in blocking the cracks in the wall of the well.

Finally, they have a set of seeds that are responsible for filling the pores in the fiber network; and they form the components of this drilling mud.

Harbor control method using fiber-based mud

In a few steps, this mud can prevent the well from being damaged by blocking the gaps in it.

In the first step, the fibers and grains in the fiber-based mud, due to being homogeneous, remain floating in the base fluid with the same dispersion and do not settle. The result of this feature is network formation and blocking gaps in the well.

In the second stage, when the protective network is formed on the gap, the presence of soft grains in the composition of this mud, the penetration of grains penetrates into the pores of the gap and creates sufficient resistance to pressures due to weight gain, cementing and continued drilling operations. In simpler terms, soft fiber, in addition to covering inside cracks, prevents hard fiber from entering the gap.

Read more: “Fluid Loss Control Additive“

The results of the application of this mud in real drilling operations

The use of this mud in real conditions has had interesting results. Regardless of what was said at the beginning of the article, the following results can be announced in this regard:

Fiber-based mud density can be changed based on the requirements and the type of operation. This will make the mud more effective in controlling mud loss.

In practice, this mud has shown that it can block gaps up to 5 mm in diameter.

Using this mud is simple and does not require different equipment. Therefore, drilling operations can be continued immediately after controlling the loss.