.In this article from Nikan west gilsonite website we discuss about the Purpose of drilling fluids or drilling mud

Drilling of deeper, longer and more challenging wells has been made possible by advances in drilling technologies such as using more efficient and effective drilling fluids.

The use of drilling mud

Drilling fluids, also called drilling mud , are added to the well to facilitate the process of drilling by controlling pressure, stabilizing the stone under pressure, creating buoyancy, cooling and lubrication.

In the early third century BC, the Chinese used water as a drilling fluid to facilitate infiltration into the earth. But the term drilling mud was coined when Spindletop has been used in the United States as drilling lubricant.

As the technology of manufacturing and chemical composition of drilling fluids has become much more complex, its functionality and concept remain unchanged. Drilling fluids are essential for drilling success, maximizing efficiency and minimizing the amount of time needed to reach the goal.

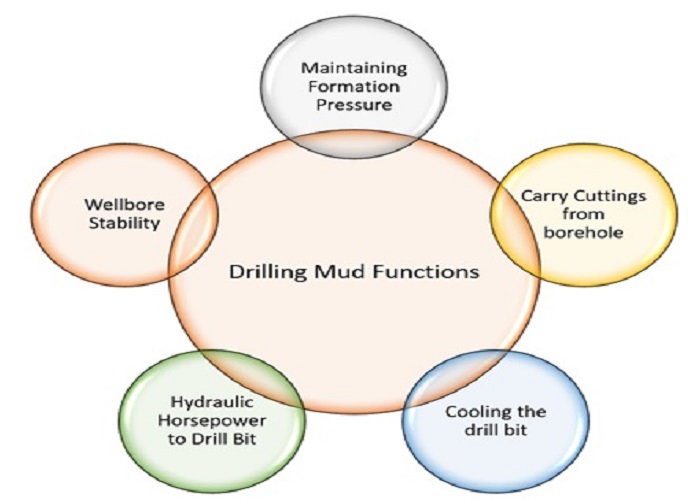

Purpose of drilling fluids

During drilling with any kind of borer, drill chips are created. These chips are crumbs created by digging the drilling site. Of course, the chips don’t matter until the drill stops, but as soon as the drill stops, the chips are thrown back into the created hole and prevent the drill from moving smoothly. Drilling fluids are used as a tool to prevent this from happening. These fluids have a certain consistency – and when the drill stops, their viscosity causes them to harden. The same feature helps the chips to get out of the borer.

Drilling mud also help to control the pressure in the well by compensating the pressure of hydrocarbons and rock formations. In fact, to increase its density and hence its pressure on the well walls, it is added to the drilling fluid of the weighting agents, which as its fluid weight increases, changes its ability to control the well pressure.

Another important function of drilling fluids is rock stabilization. These fluids use special additives to ensure that the drilling fluid is not absorbed by the rock formation in the well and that the pores of the rock formation are not blocked.

The deeper the well, the more drilling pipes are required. With this amount of pipe, the drill becomes heavy, and therefore, the drilling mud increases buoyancy and reduces the pressure. In addition, the drilling fluid helps to reduce friction and heat. This lubrication and cooling help to extend the life of the borer.

what are Drilling fluids ?

Drilling fluids are water, oil, or synthetic-based; each combination offers different solutions in the well. If the rock is made of salt or clay, appropriate action must be taken to make drilling fluids effective. In fact, a drilling fluid engineer performs drilling monitoring operations and adds the necessary drilling fluid additives throughout the process to speed up digging or to minimize friction.

A drilling fluid engineer should consider environmental impacts when prescribing the type of drilling fluid in addition to the chemical composition and properties of the well. Oil-based drilling fluids may work better with a saltwater rock. Water-based drilling fluids are mostly used in offshore drilling environments.

Disposal of drilling fluids after use can also be a challenge. Recent technological advances have created methods for the recovery of drilling fluids, which in addition result in saving the cost of drilling fluids, reducing the environmental damage of drilling fluids and drilling chips in the environment. If you want to buy gilsonite , gilsonite powder and natural bitumen you can contact with Nikan West Gilsonite company.